Field Joint Coatings

In the area of Field Joint Coating, JURUNATURE continues to provide best in class service to the industry and through its partnership with RAE Energy, we strive to offer innovative solutions that ensure the Field Joint Coating application remains off the critical path of pipe laying.

We are firmly focused on our Client Charter of providing these services in a cost effective and timely manner whilst remaining true to our doctrine on Health, Safety, Environment and Quality.

TRAIN TO EXCEL & EXCEL TO BE SAFE

WHY APPLY MECHANICAL PROTECTION ?

Assets, such as offshore pipelines, risers, spools or structures, may experience impact or abrasion after they have treated the external surfaces with an anti-corrosion coating. These impact loads or abrasions may occur during transport between the anti-corrosion coating site to the assets final location or during the installation phase (lifting equipment, assembly at spoolbases or on offshore vessel) or during pipeline operations (ploughing, trenching, fishing equipment, dropped objects etc). To reduce the risk of damage to the anti-corrosion coating, a second layer of material is applied to provide mechanical protection throughout the life of the asset. This protection can avoid the cost of intervention, a high cost in offshore projects in deepwater locations.

The cycle time to apply and cure the mechanical protection coating for assets (particularly field joints onboard S-Lay vessels) is critical. To achieve the fastest and reliable cycle times, training of the JURUNATURE / RAE application crew, formulation of material properties (particularly curing time and impact strength) and the design of fast and reliable equipment is essential.

FJ 3000- For CWC field joints requiring high density infill, JURUNATURE / RAE offers our FJ 3000 Infill Application (see products section). Aggregate is placed within the field joint annulus and the JURUNATURE / RAE formulated elastomer FJ 3000 is injected into the mold and fills the voids between the aggregate.

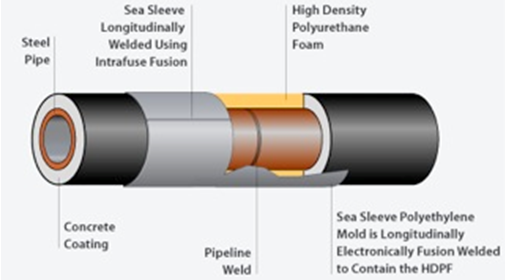

HDPF is produced in various densities for field joint infill on concrete coated pipe to meet the modern demands of the pipeline infill market. A patent is held for "Sea Sleeve", a dispensable polyethylene mold which is welded, using their "Intrafuse" system, around the field joint to form the annulus for filling. HDPF can also be applied using re-usable molds.

Concrete Weight Coating (CWC) Infill Applications

- Mechanical Protection

- Anti-Corrosion Applications

- Fusion Bonded Epoxy

- Liquid Epoxy

- Three Layer Polypropylene (3LPP) Application

- Serviwrap Anti Corrosion

- Cold Applied Tape System

ANTI CORROSION APPLICATIONS

The cycle time to apply and cure the anti-corrosion coating for offshore assets, particularly field joints at spool bases and onboard S-Lay and J-Lay vessels is critical. To achieve the fastest and reliable cycle times, training of the JURUNATURE / RAE application crew, selection of material properties (particularly curing time) and the design of equipment is essential.

FUSION BONDED EPOXY

The FBE Application System requires the steel pipe to be grit blasted to clean the steel and provide a profile to promote a bond between the steel and the epoxy. After blasting, the area is pre-heated to approximately 230 degrees C and then the FBE in a powder form is applied to the area and overlapping onto the parent FBE coating. JURUNATURE / RAE offers our High Speed FBE Application system which holds the world record for lay rate on offshore pipelines at 9.2 Km per day.

LIQUID EPOXY

The LE Application System requires the steel pipe to be grit blasted to clean the steel and provide a profile to promote a bond between the steel and the epoxy. After blasting the area is pre-heated to the manufacturers recommended temperature (approximately 80 degrees C) and then the LE is brushed onto the steel exposed area and overlapping onto the parent anti-corrosion coating. Post heat can be used to cure the epoxy faster.

THREE LAYER POLYPROPYLENE (3LPP) APPLICATION

JURUNATURE / RAE offers PolyFuse application equipment which applies a 1 mm thick film of polypropylene over the field joint. The field joint is coated with FBE then the film of PP is wrapped around the field joint and overlapping onto the parent coating. The PP film fully fuses with the parent PP coating. Usually 3 wraps of the PP film is applied to obtain a total of 3 mm thickness. The application cycle time is 6 minutes for 12 dia pipe. The temperature range is minus 50 deg C to 115 deg C. JURUNATURE / RAE equipment is fully automated to ensure repeatability of the high quality field joint.

SERVIWRAP ANTI CORROSION

For the protection of butt weld joints against corrosion damage on concrete weight coated submarine pipelines, where the joints will be infilled with HDPF/SPU or other forms of infill materials.

SYSTEM

A two component cold applied tape system, consisting of a PVC carrier, plus a self adhesive compound. The main role of the carrier is to bring the tape's adhesive compound to the pipe's surface and to provide mechanical and heat protection whilst the joint area is being infilled. Once the joint is completed, the tape's adhesive compound provides the anti-corrosion coating and the marine mastic, or other infill material, the primary mechanical protection.