ProTXcoat - High Temperature Insulation and Repair Coating

ProTXcoat Coatings and Repair Materials Technology

ProTXcoat is manufacturing of engineered epoxy (novolacs) and polyurethane repair compounds and coatings. ProTXcoat was founded by the leading R&D experts and Application Engineers in the field of Composite Coating with decades of application experience! Our products and know-how are supplied to countries worldwide and are used by some of the largest companies globally.

ProTXcoat Corrosion Protection products are used in many industries and through our extensive worldwide network of contractors we are able to offer onsite technical support, training, presentations & seminars backed by project method statements & specifications.

We specialize in offering solutions against abrasion, wear, impact, chemical attack, leak repair and corrosion on process systems and equipment.

ProTXcoat combines two decades of know-how with service to: Petro Chemical Plants, Chemical Plants, Pulp and Papermills, Cement plants, Power Generation, Marine and Offshore, Food and Pharma, and general manufacturing.

Metal

- Corrosion (Corrosion Protection System)

ProTXcoat Corrosion Protection products are ideal for protecting metallic and concrete surfaces from strong chemicals, weathering and UV degradation.

- Abrasion - Abrasion, Erosion, Wear and Impact Protection

The type of wear where particles move freely across a surface. Unless the metal is hard enough to resist, the particles cut grooves into the surface and cause costly shutdowns and replacements.

- Chemical Attack

Our Chemical Protection Coatings have been independently tested in full chemical immersion in industrial chemicals such as 98% Sulphuric Acid, Sodium Hypochlorite, 37%Hydrochloric Acid and Sodium Hydroxide.

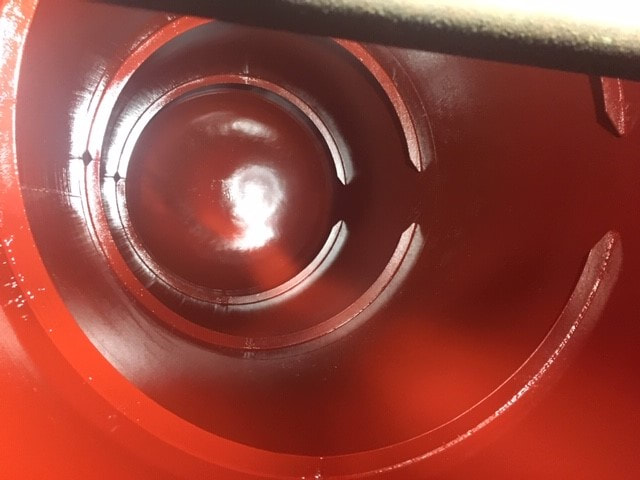

- Pump Repair

Our pump repair and lining materials are proven to protect metallic surfaces from sea, river, drinking and waste water, as well as giving excellent resistance to a wide range of industrial chemicals.

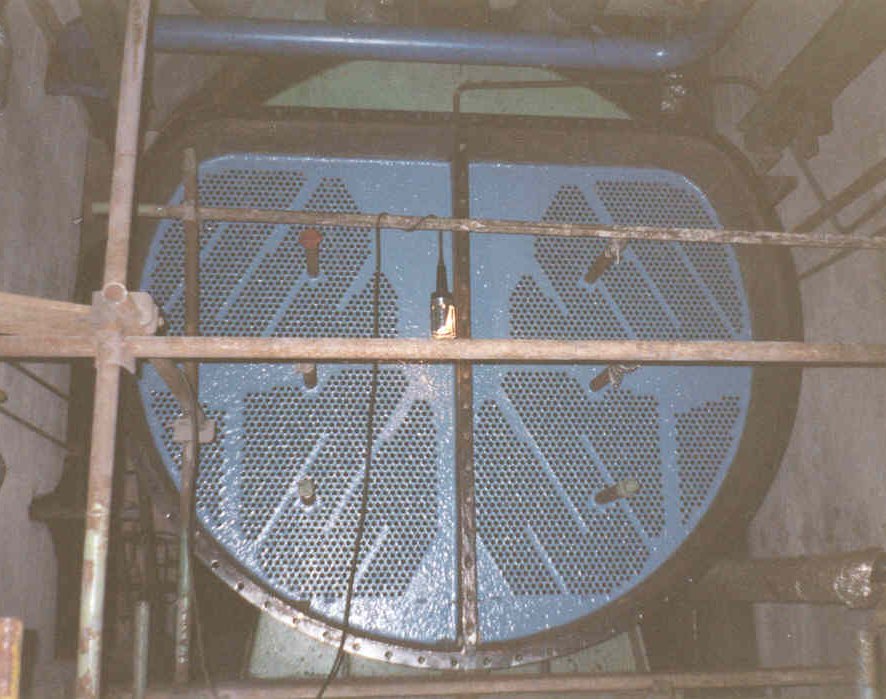

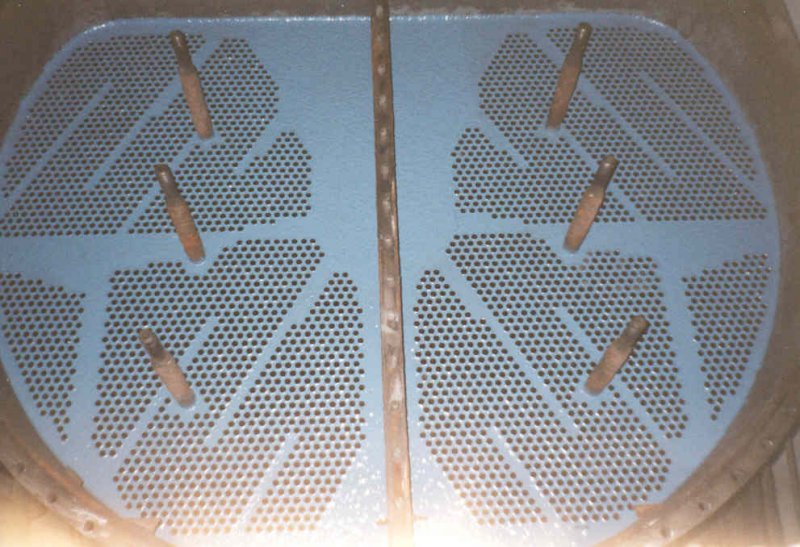

- Heat Exchangers

ProTXcoat offers an extensive range of epoxy-based metal repair materials and ceramic coatings designed to repair and protect heat exchangers from erosion and corrosion.

- Flange Repair and Reforming

ProTXcoat two component solvent free epoxy Novolac coating designed for high temperature immersion conditions. Once cured it can withstand continuous immersion conditions up to 150°C and can upgrade the performance of conventional materials of construction.

- Pipeline Coatings

Sustainable eco-efficient Pipeline-coatings and asset conservation. ProTXcoat offers Epoxy and Polyurethane systems for optimal protection in harsh environments.

- Tank and Vessels

ProTXcoat offer rigid protection to steel and concrete tanks and storage basins.

Concrete

- Concrete Repair

A fast curing 3-part concrete mortar which is ideal for repairs to damaged concrete surfaces.

- Concrete Protection

ProTXcoat has a diverse range of concrete repair materials that can repair badly damaged cementitious surfaces and protect them from wear, abrasion and chemicals

- Containment Areas

ProTXcoat Chemical Containment coatings offer outstanding chemical resistance to a wide range of industrial chemicals.

- Safety Flooring

ProTXcoat floor coatings and screeds providing highly durable and wear resistant surfaces.

- Self-Levelling Floor Systems

ProTXcoat floor coatings are a range of solvent free epoxy resin based systems ideal for resurfacing and rebuilding concrete surfaces.

Maintenance

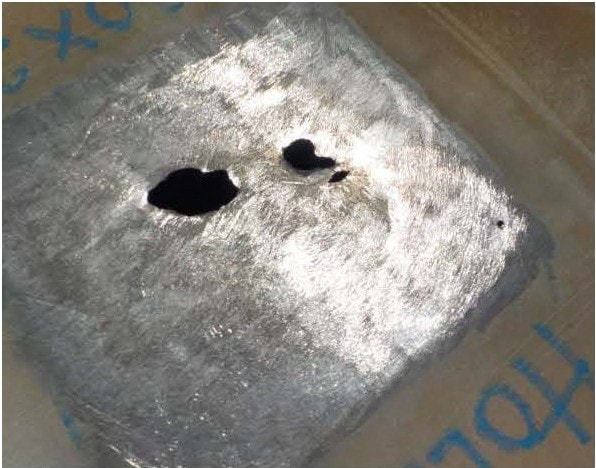

- Leak Repair

ProTXcoat pipe repair and pipe wrapping materials can be used to isolate and seal small pinholes or cracks in process pipework, or used to encapsulate long lengths of large diameter pipe.

- Plate Bonding

ProTXcoat metal repair systems are recognized throughout industry as a credible alternative to welding. Seal leaking tanks & pipes, cold bond irregular shaped surfaces by using our epoxy metal repair systems

- Maintenance Repair and Overhaul Supplies

ProTXcoat has a wide range of products ideally suited to the Maintenance, Repair and Overhaul market. From metal repair to underwater repair and concrete repair materials, our product range is used across the world to repair, protect and upgrade components, equipment and process systems.

Roof and Waterproofing Systems

- Waterproofing and Sealing

Range of single component waterproofing materials is able to seal virtually any surface with a strong, flexible membrane to give long term protection from UV degradation and weathering. The ProTXcoat range of waterproofing materials includes water-based acrylic, solvent based acrylic & solvent based polyurethane coatings.

- Gutter Repair

ProTXcoat offers a range of solvent based and water-based roof and gutter repair membranes that are designed to seal and protect bitumen, concrete, metal and GRP surfaces.

- Roof Repair

ProTXcoat roof and gutter membranes give year-round coating capability, and can even seal leaking roof surfaces through ponded water.

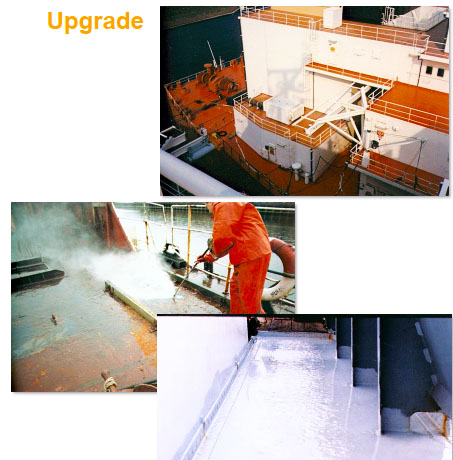

Marine and Offshore

- Onboard Repair Kits and Marine Coatings

ProTXcoat’s comprehensive range of rapid and cold-curing marine coatings and metal repair composites has been used by the marine industry for many years. Our products are specifically designed to withstand harsh offshore conditions and have exceptional resistance against erosion and corrosion.

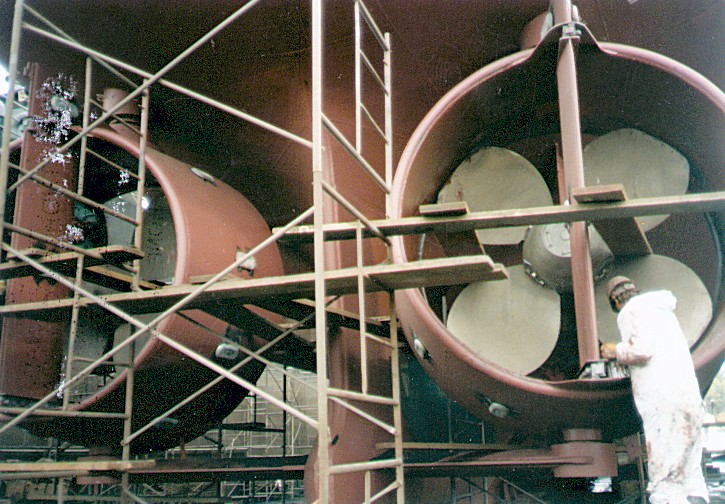

- Rudder and Propeller Repair

ProTXcoat ceramic enhanced coatings and engineering repair materials can be used to rebuild, resurface and protect metallic surfaces subject to cavitation, bi-metallic corrosion and abrasion.

- Hull Coatings

ProTXcoat offers a wide range of coating systems for both Dry-Dock repairs, new builds and onboard maintenance.

- Leak Repair

Range of pipe repair materials are based on the latest epoxy and polyurethane resin technology. ProTXcoat pipe repair and pipe wrapping materials can be used to isolate and seal small pinholes or cracks in process pipework, or used to encapsulate long lengths of large diameter pipe.