(Jurunature's Awards)

Kindly click here to see all Jurunature's Awards and Recognitions

Majlis Iftar dan Solat Terawih 1445H/2024 bersama YBHG Pof. Madya Dato' Dr. Mohd Farid Ravi bin Abdullah

(30 Mar 2024)

More photos can be viewed at gallery

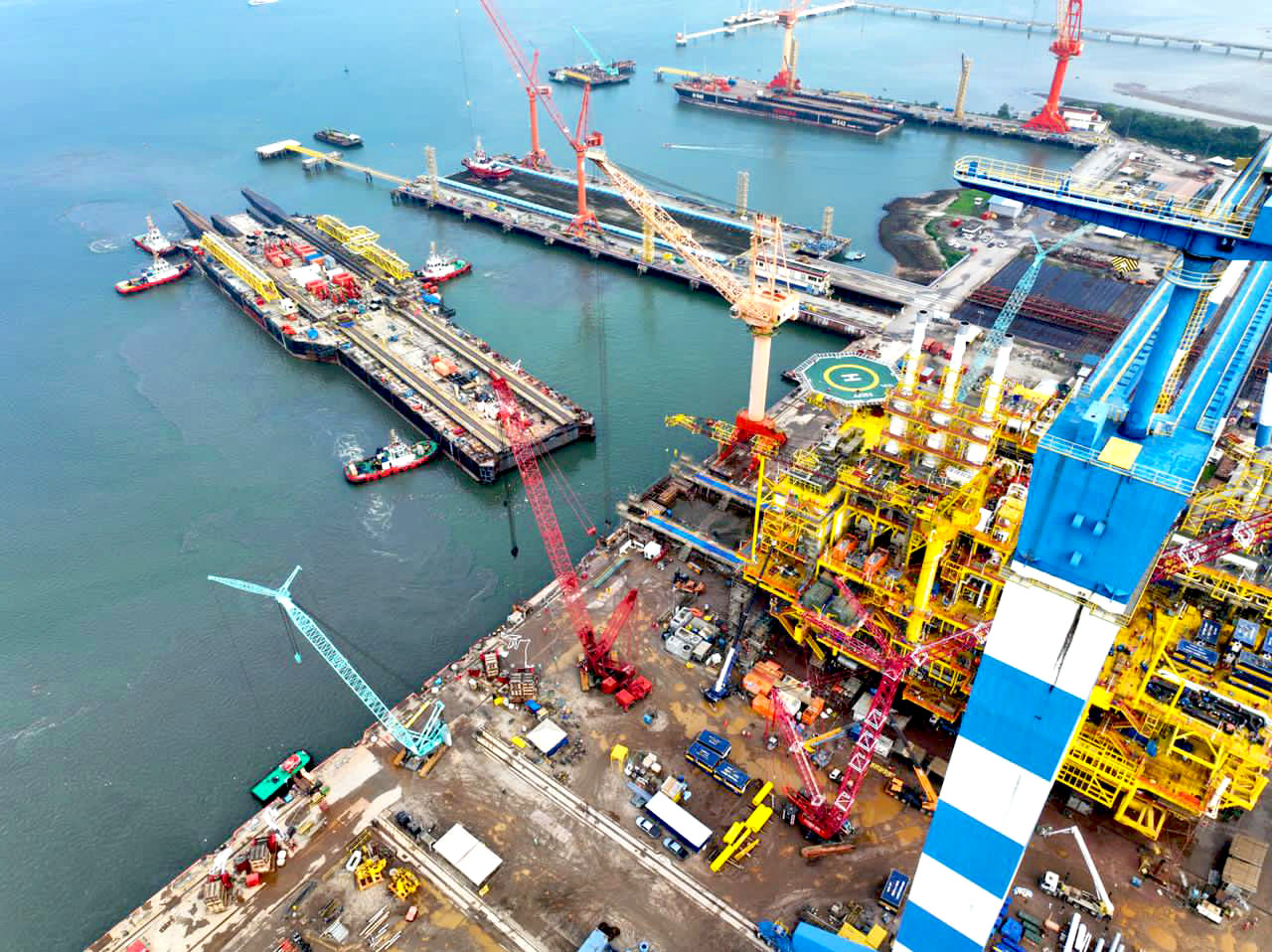

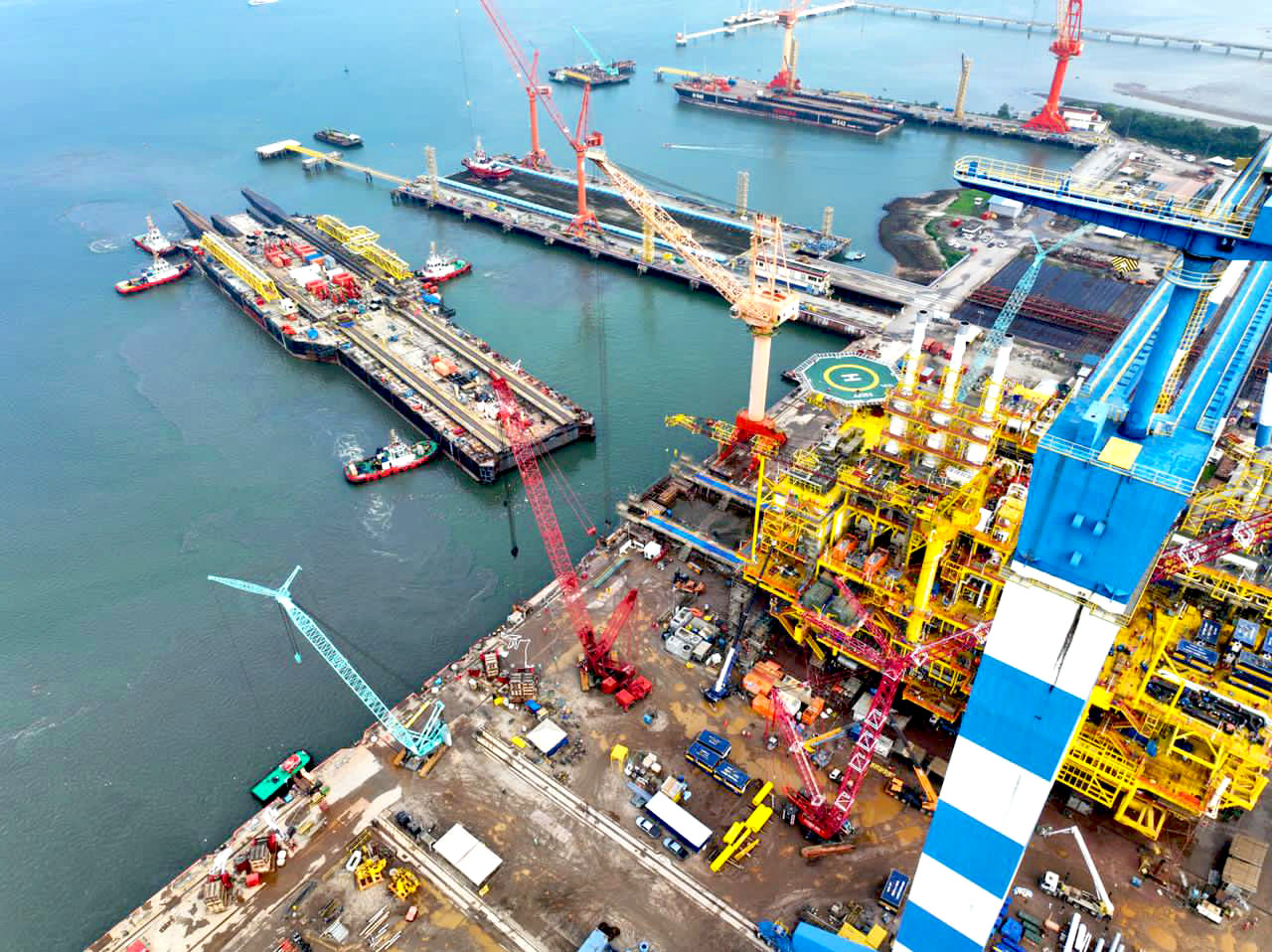

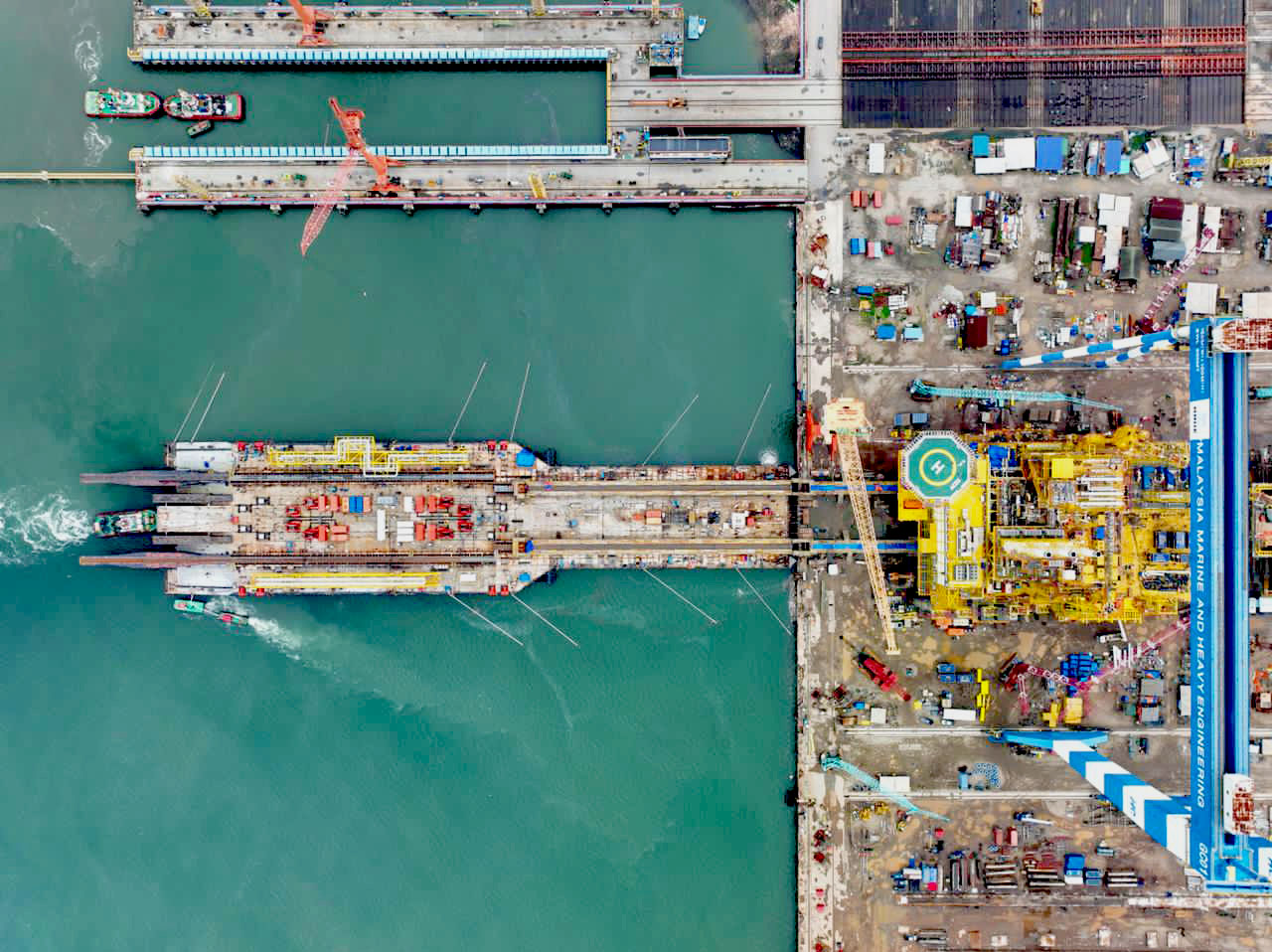

JERUN Development Project - JRN-A CPP Topside Sailaway

(25 Feb 2024)

Click here to view gallery

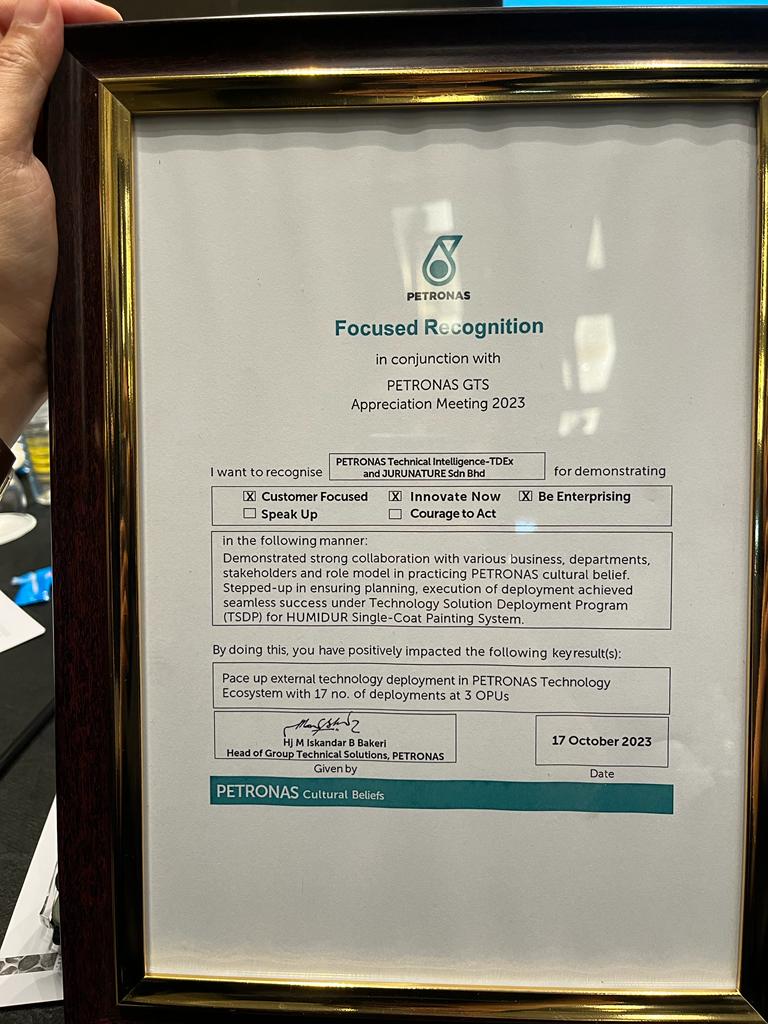

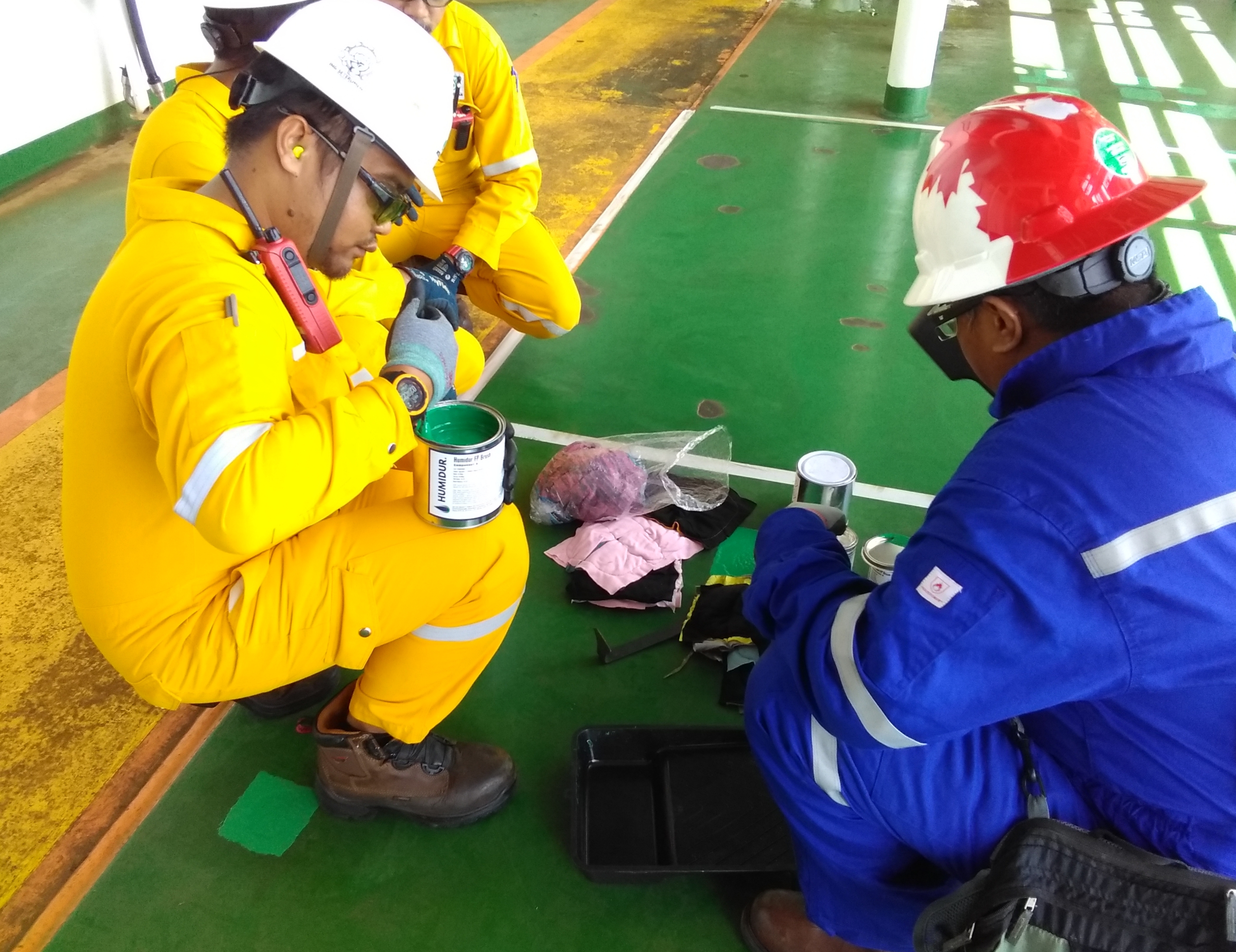

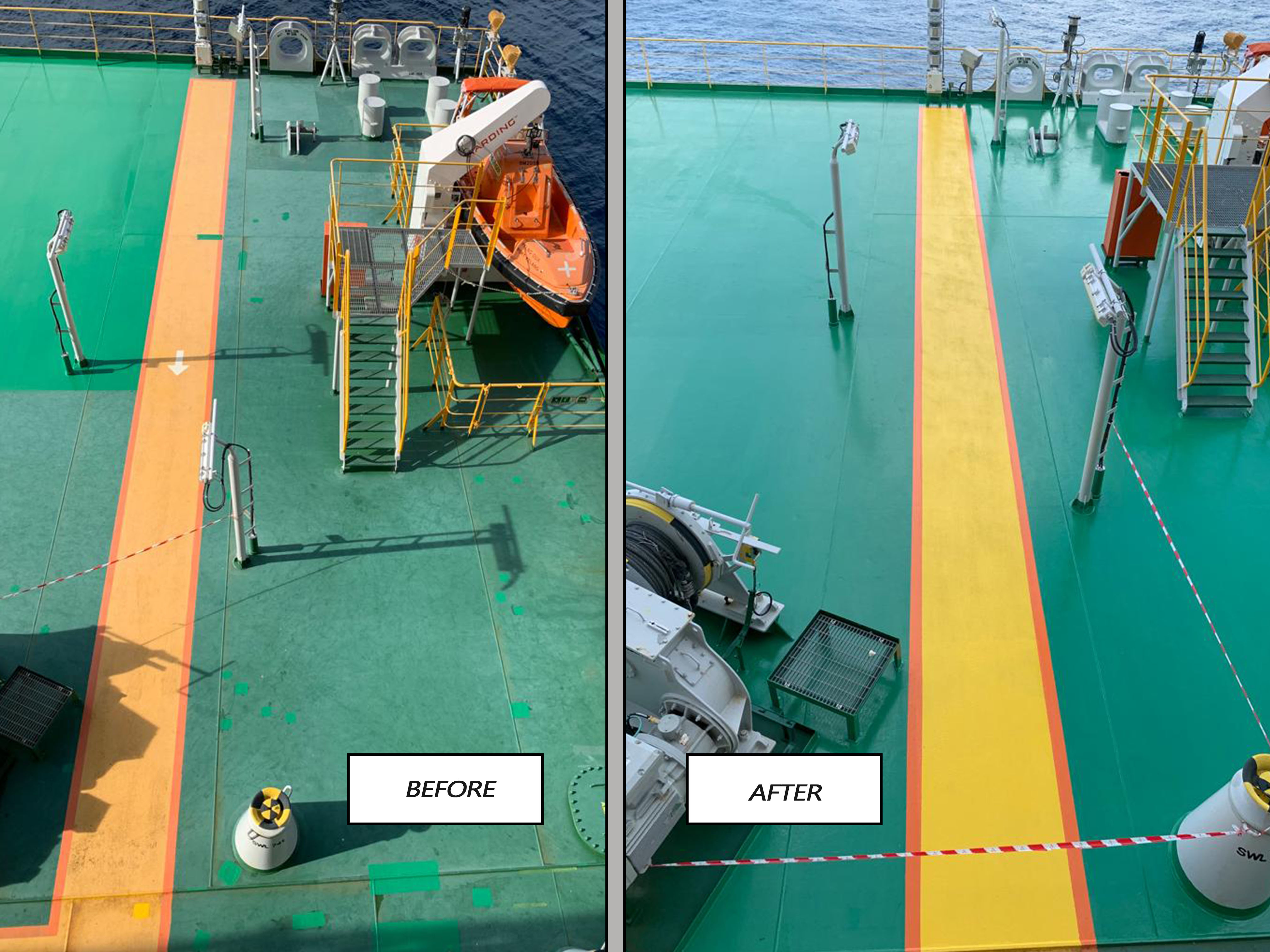

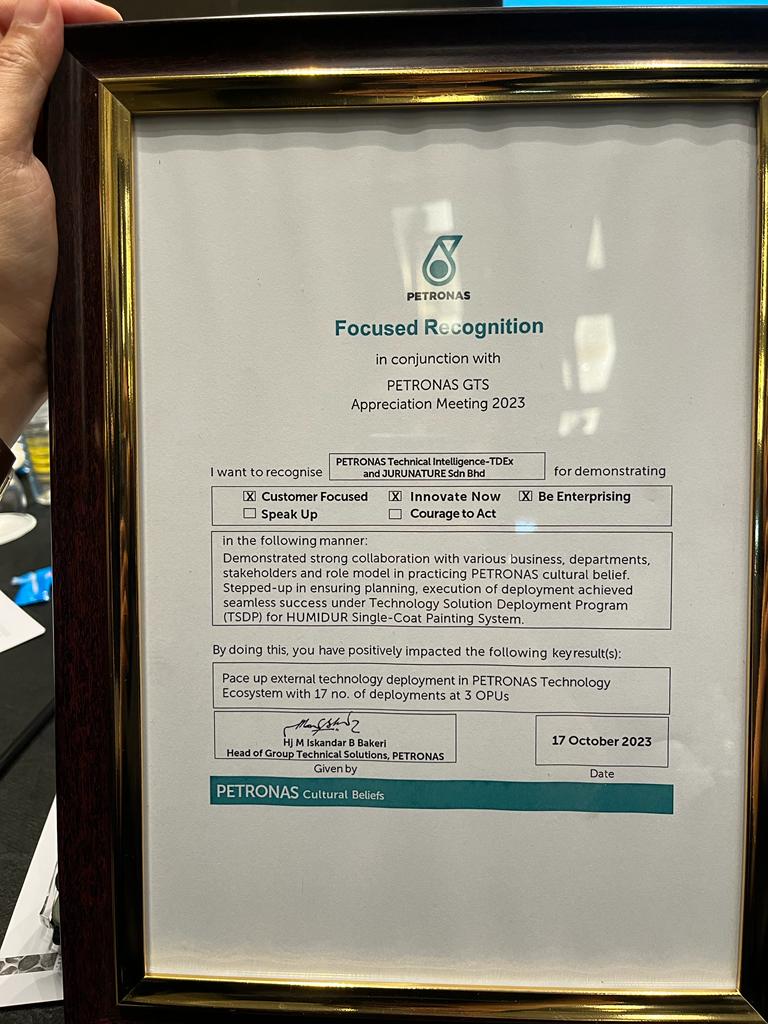

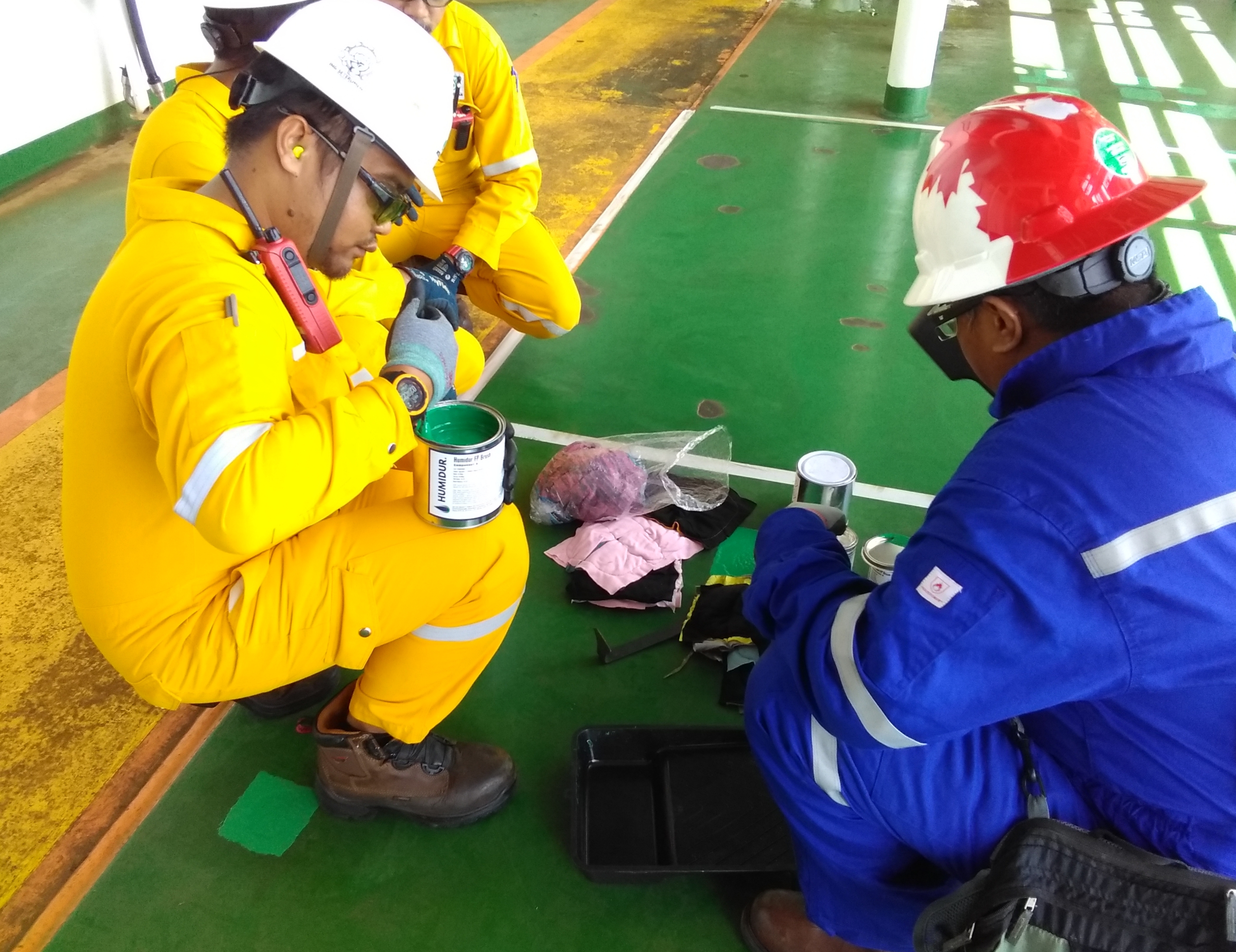

PETRONAS Technology Solution Deployment Program (TSDP) for the Humidur Single Coat

(17 Oct 2023)

Alhamdulillah, Jurunature has been recognized by Petronas for its strong collaboration across various businesses, departments, and stakeholders. We’ve been commended as a role model for embodying PETRONAS's cultural beliefs. We've consistently stepped up to ensure that planning and execution of the Technology Solution Deployment Program (TSDP) for the Humidur Single Coat system achieve seamless success.

Click here to view gallery

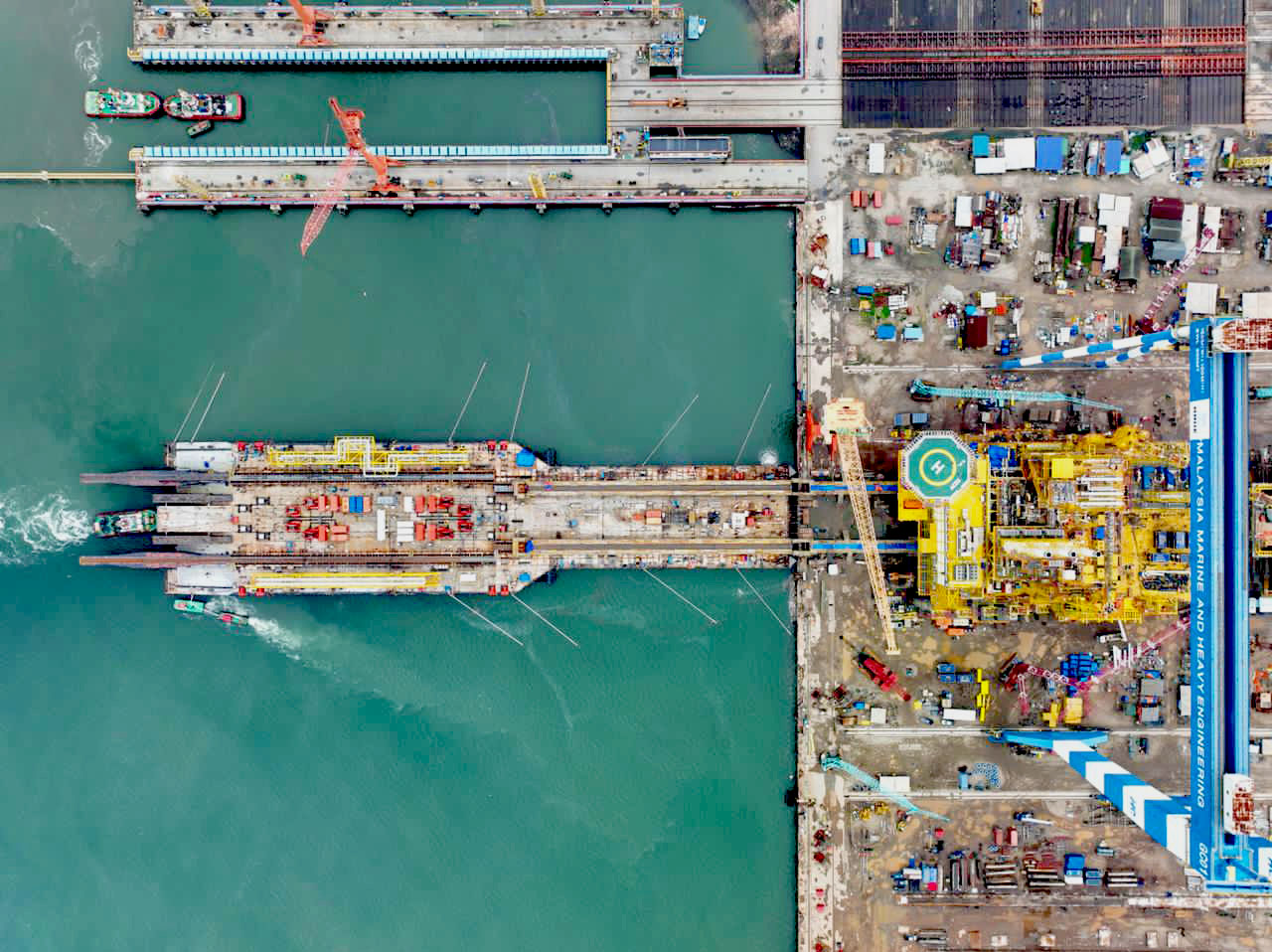

KASAWARI Gas Development Project - CPP Sailaway

(August 2023)

Please click this photo to play video

Click here to view gallery

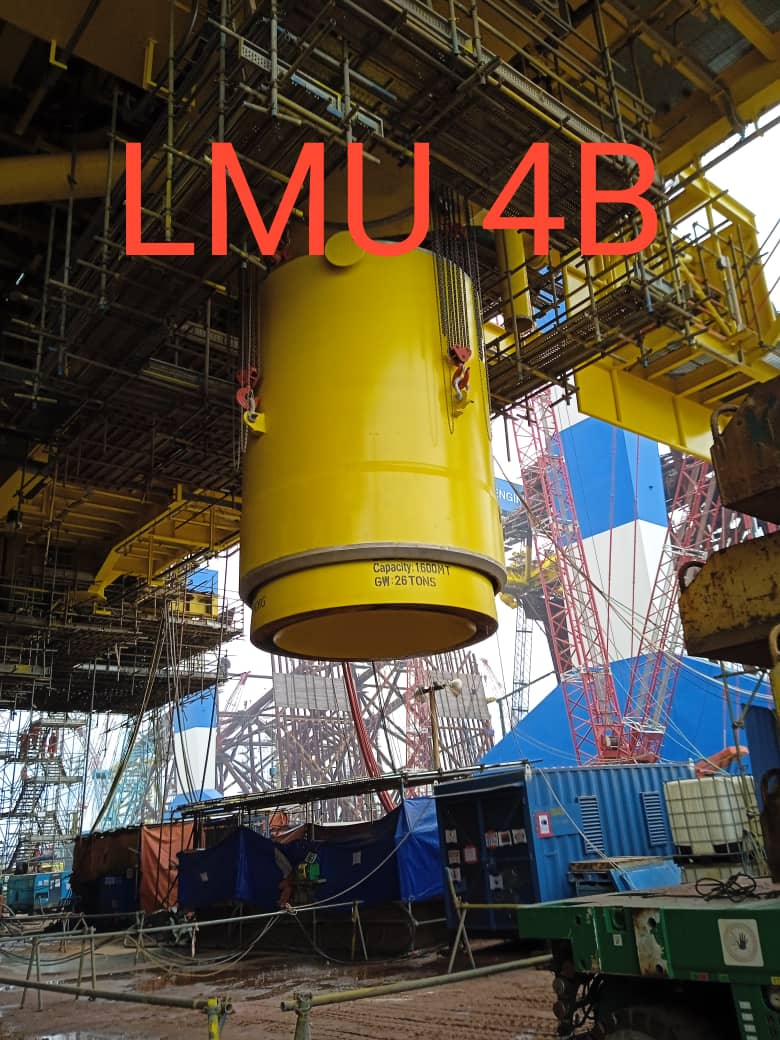

KASAWARI Gas Development Project - Along Side Activities

(31 Jul 2023)

Click here to view gallery

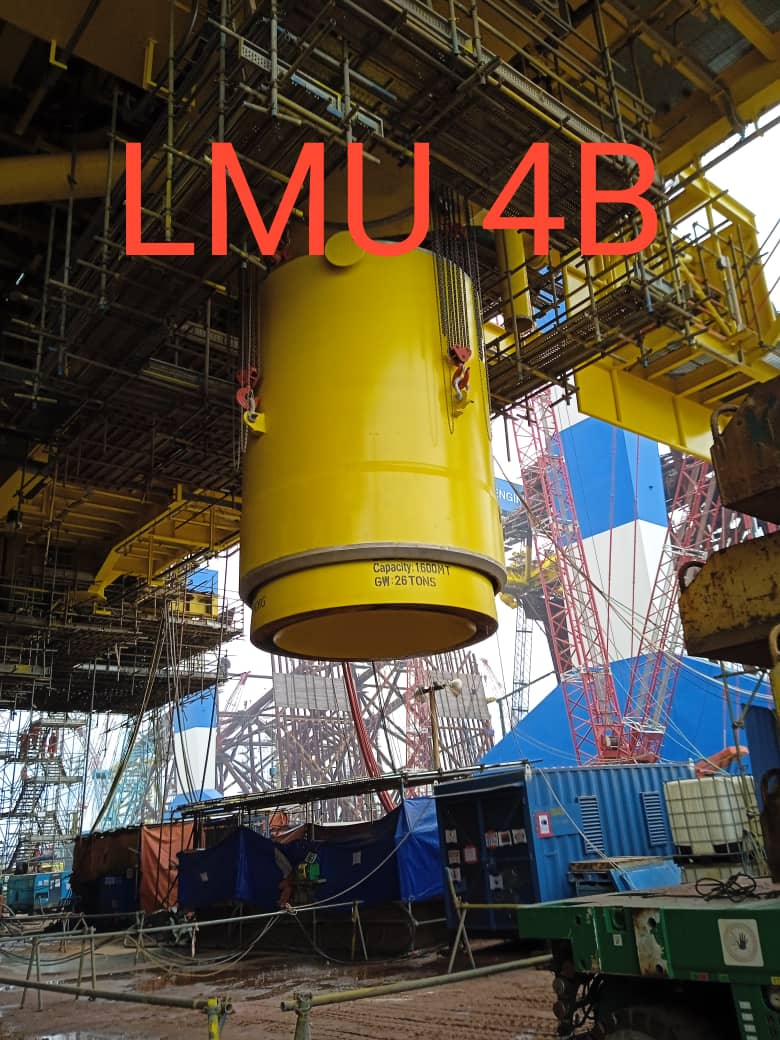

KASAWARI Gas Development Project - CPP Loadout

(Jul 2023)

Click here to view gallery

E11RA - Project Completed Successfully

(May 2023)

.jpg)

.jpg)

Click here to view gallery

Jurunature Sdn. Bhd. mengucapkan Selamat Hari Raya, Maaf Zahir dan Batin kepada semua muslimin dan muslimat

(1444H/2023M)

Tangan dihulur maaf dipohon

Tanda ikhlas mensucikan diri

Salah dan silap mohon diampun

Semoga gembira di Aidilfitri

Klik di sini untuk menonton klip Hari Raya kami

Majlis Iftar dan Solat Terawih bersama YBHG Pof. Madya Dato' Dr. Mohd Farid Ravi bin Abdullah

(April 2023)

More photos can be viewed at gallery

E11RAA Project - Jacket loadout

(March 2023)

Alhamdulillah another successful cross over!

Click here to view gallery

Strategic Partnership - Jurunature and ABYSS Solution

(December 2022)

A good start in year 2023 is what boosts up our confidence, and hence Jurunature is happy to announce our new business partner Abyss Solutions the home of the world’s brightest minds in autonomy, data analytics, data science, and robotics.

A journey of a million steps starts with a single one, and let’s remember this day as the future holds many special gifts for us hence let us hopes for a better future.

Making autonomous inspection accessible at scale !

Browse to abysssolutions.co for more information.

KASAWARI Gas Development Project - December 2022 Progress

(December 2022)

Click here to view gallery

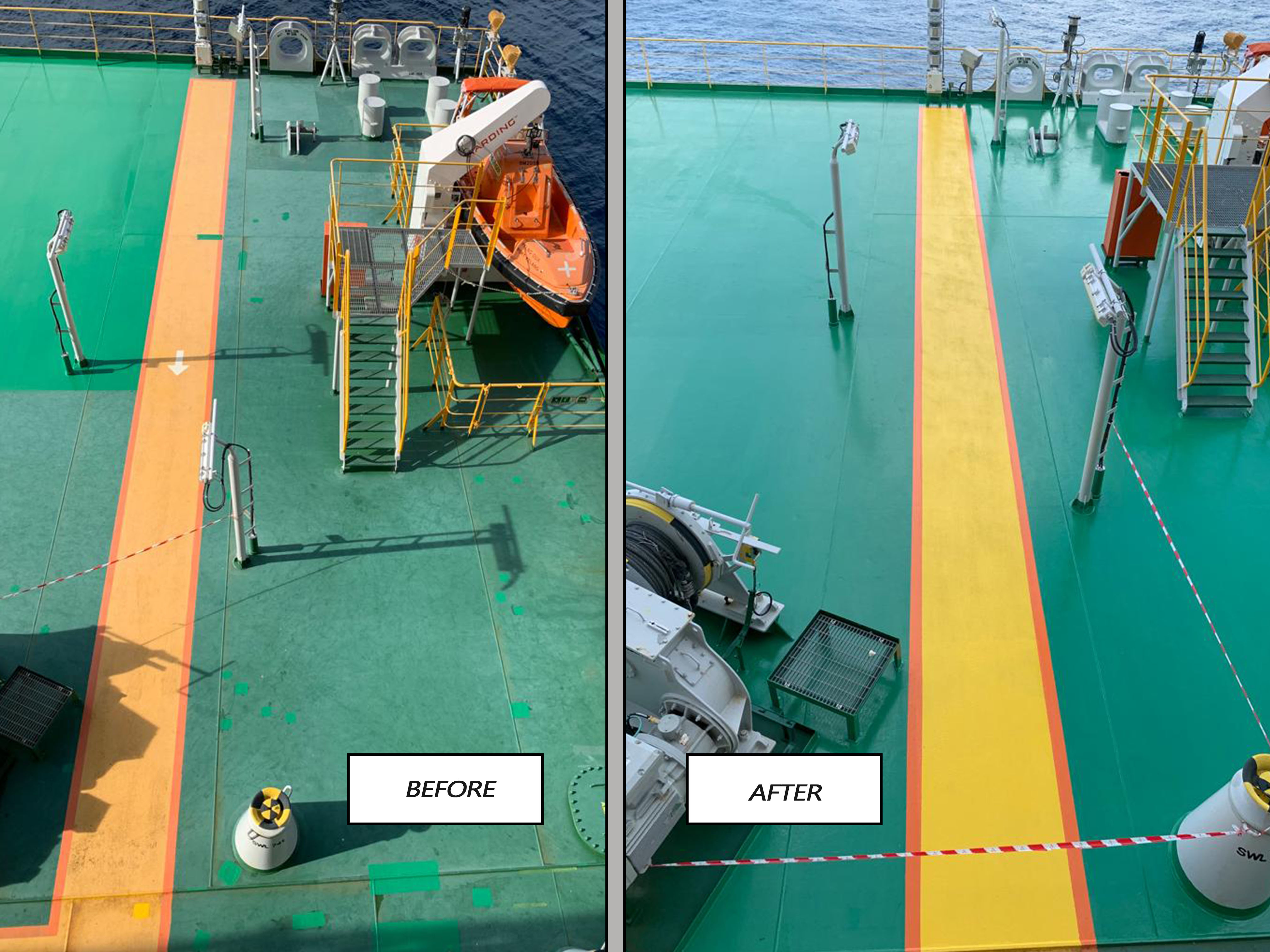

Humidur Painting Scope at PETRONAS FLNG (PFLNG)

(Jul - Dec 2022)

Offshore Coating Maintenance and Humidur Training to PFLNG crews.

More photos can be viewed at gallery

"Petronas anugerah kontrak 5 tahun kepada Jurunature bekal, selenggara produk Humidur" - ASTRO Awani

(30th Jul 2022)

.jpg)

News about JURUNATURE Sdn Bhd awarded with 5 year contract from PETRONAS appeared in ASTRO Awani portal.

Click here to read the full article form ASTRO Awani portal.

Please feel free to contact us at humidur@jurunature.com for more details of the Humidur products.

Acotec Humidur Joins Jurunature to Meet Growing Demand in the Asia Pacific Market

(16th June 2022)

Acotec Humidur® has entered into a joint venture with Jurunature Sdn Bhd following the growing demand in the Asia Pacific market.

Read more: https://lnkd.in/e3QrS9M6

#myipcm #Humidur #jointventure

Humidur and Humidur Char - By Acotec NV

5 year contract from PETRONAS for the Provision of Supply, Installation and Maintenance Services of HUMIDUR Products

(June 2022)

JURUNATURE Sdn Bhd is pleased to announce the award of a 5 year contract from PETRONAS for the Provision of Supply, Installation and Maintenance Services of HUMIDUR Products to all PETRONAS assets effective June 2022.

Please feel free to contact us at humidur@jurunature.com for more details of the Humidur products.

Humidur Manufacturing Plant in Malaysia

(11th May 2022)

We are pleased to announce the official opening of the Joint Venture Manufacturing plant of the Humidur products in Malaysia to cater for the Asia Pacific needs.

The jointly owned company by the owners of both Humidur and Jurunature, called Jurunature Humidur Asia Pacific Sdn Bhd, will manufacture Humidur products to cater for all the client needs in the region and to complement Humidur production capabilities and capacities in their main plant in Belgium.

Read more: Linkedn, Instagram

#team #business #manufacturing #quality

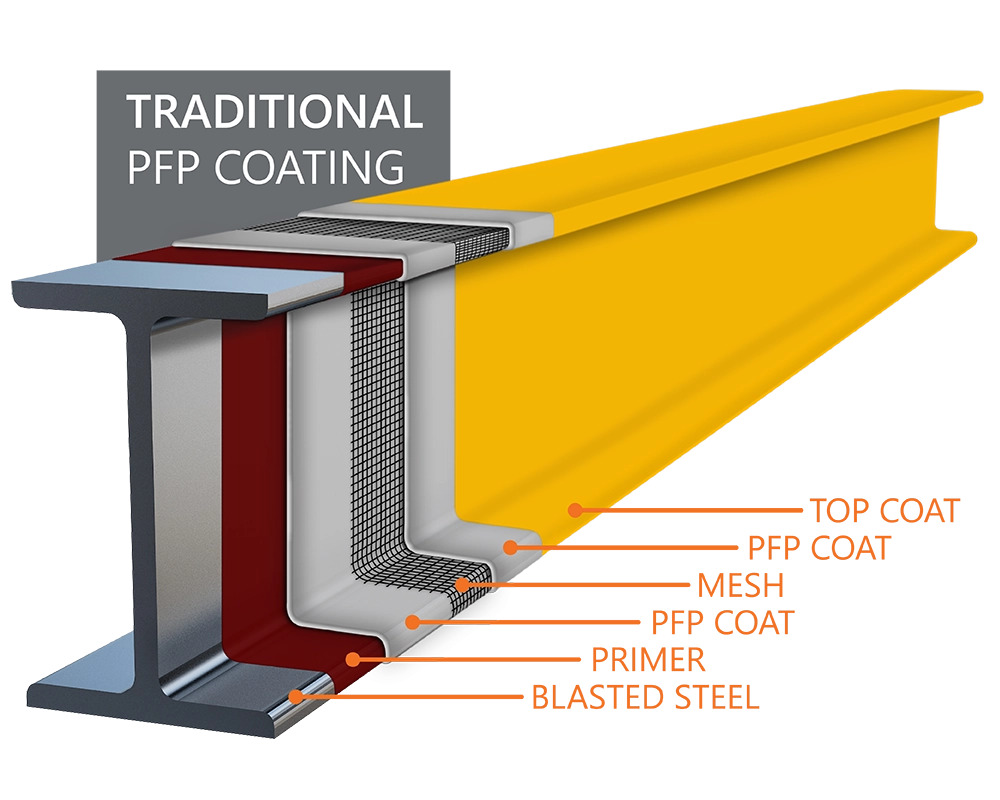

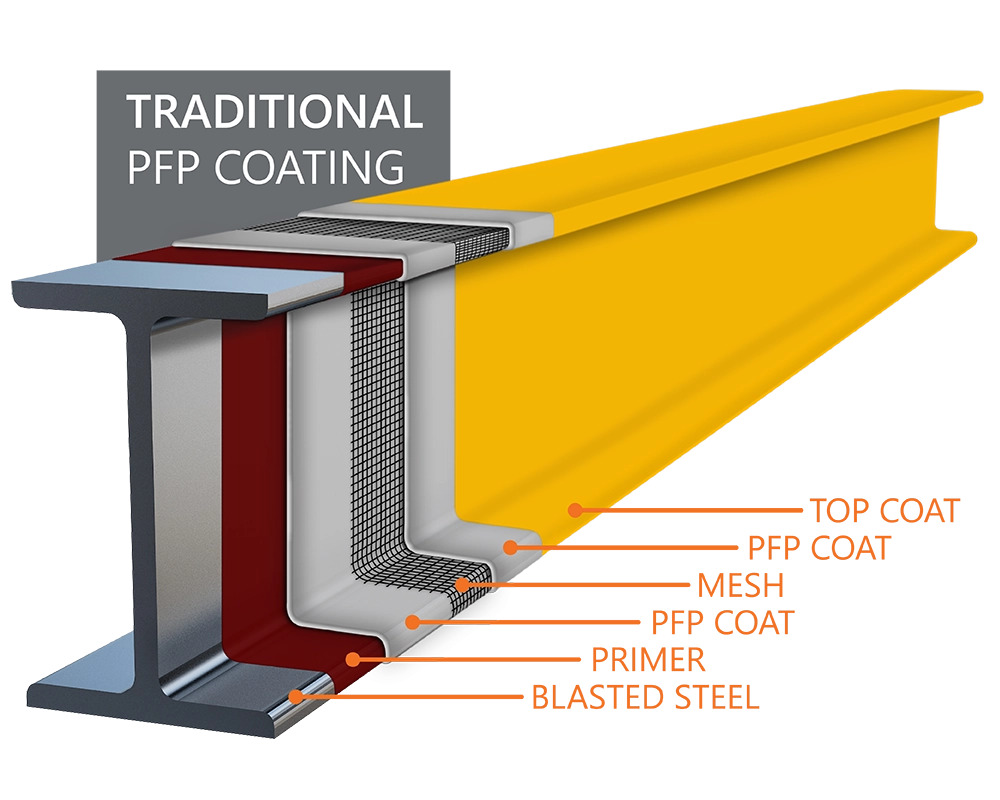

Acotec Launches One-coat PFP with Humidur Char

(09th May 2022)

A new sustainable PFP coating system Humidur®Char will change the way PFP is applied

Humidur Char, launched by Acotec, is a two-component, solvent-free, 100% solids, polyamine cured epoxy PFP system, which offers anti-corrosion and fire resistance properties by intumescent action in one coat. A major difference with the traditional PFP coating process, that requires up to five coats.

Humidur® Char can be applied in one layer on minimum preparation standards with no primer nor mesh required and will still provide the essential Passive Fire Protection on the structural steel, used within the global Oil, Gas & Chemical industry. Not only does this revolutionary coating enable improved cost management, moreover it significantly reduces the manhours up to 50%.

Source: Coatings World, Humidur.be

KASAWARI Gas Development Project - June 2022 Progress

(June 2022)

Click here to view gallery

KASAWARI Gas Development Project - Shifting of E11RAA Topside

(April 2022)

.jpeg)

.jpeg)

Shifting of E11RAA Topside from Mega Workshop to Fab 5 successfully and safely executed today. Alhamdulillah!

Click here to view gallery

KASAWARI Central Production Platform - Loadout Support Frame Shifting (948 MT)

(January 2022)

Click here to view the video clip

.png)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpeg)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)